- TOP

- Sustainability

- Sustainability Management: Materiality

Materiality

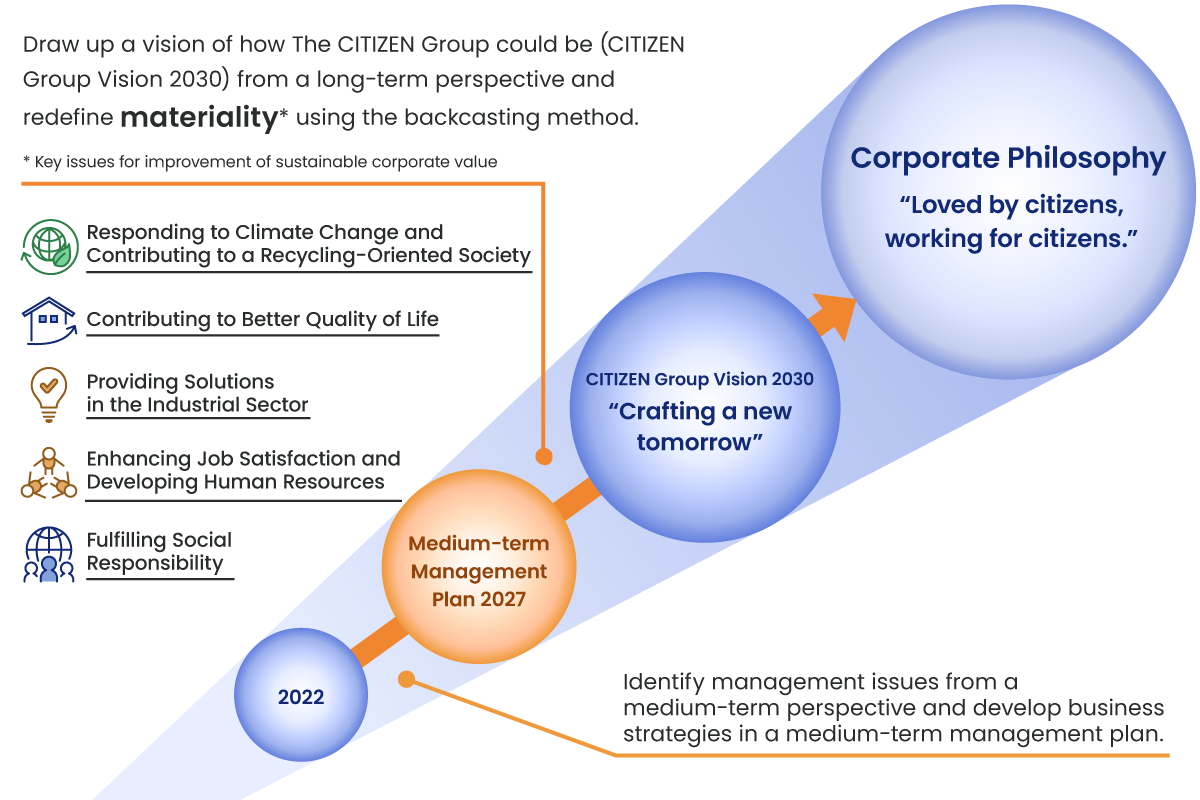

Drawing up a vision of how The CITIZEN Group could be from a long-term perspective, The CITIZEN Group formulated the CITIZEN Group Vision 2030, "Crafting a new tomorrow," in April 2022.

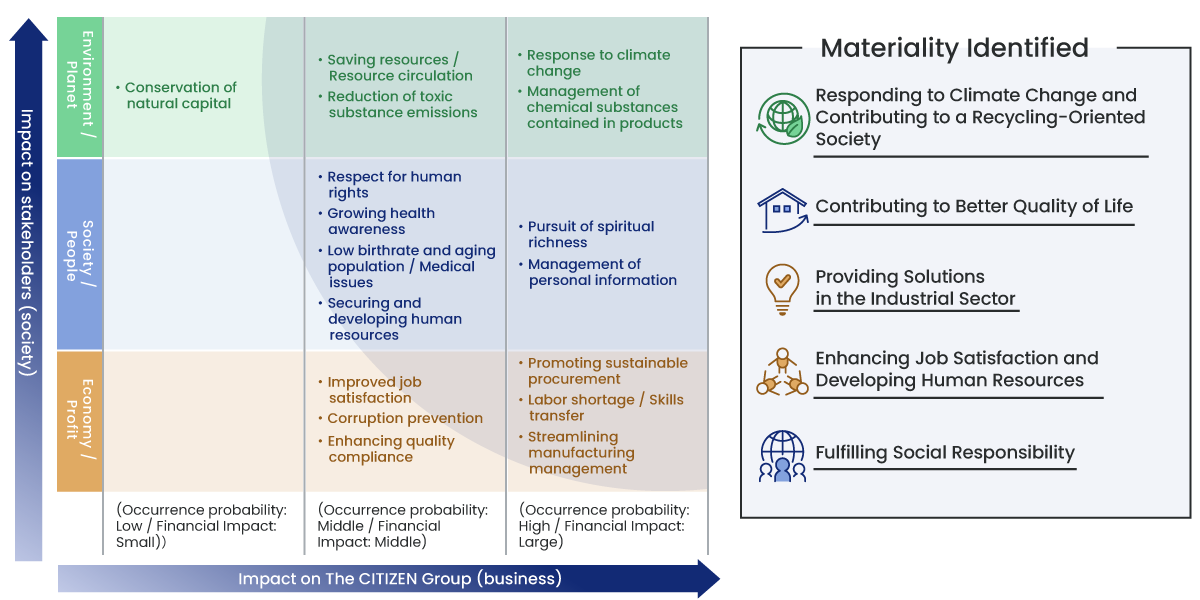

In order to realize the vision, we have identified five material issues by organizing The CITIZEN Group's material issues (key issues for improvement of sustainable corporate value) from both internal and external perspectives in terms of business activities and management foundation.

Materiality Identification Process

-

- Step 1: Identification of Social Issues

-

Identify social issues based on mid- to long-term social trends, the company's direction, ESG external assessments, reviews, etc.

- * Reference: SDGs, macro trends in environmental, social, and economic fields, FTSE, MSCI, GRI Standards, ISO 26000, etc.

-

- Step 2: Materiality Assessment of the Social Issues

-

Assess the impact on society and the importance of the materiality to the company, and make assumptions about the proposed materiality.

-

- Step 3: Assess the Appropriateness of the Proposed Materiality

-

After checking with external experts and a discussion by the Sustainability Committee, reconsider the materiality plan in light of the relevant measures for each business.

-

- Step 4: Identification of the Materiality

-

Materiality is identified by the Management Committee and Board of Directors after reaffirmation by the Sustainability Committee.

Materiality Opportunities and Risks

Please scroll down to see→

| Materiality | Opportunity | Risk |

|---|---|---|

| Responding to Climate Change and Contributing to a Recycling-Oriented Society |

|

|

| Contributing to Better Quality of Life |

|

|

| Providing Solutions in the Industrial Sector |

|

|

| Enhancing Job Satisfaction and Developing Human Resources |

|

|

| Fulfilling Social Responsibility |

|

|

Materiality Classification and Measures

Please scroll down to see→

| Materiality | Classification | Measures | Watches | Machine Tools | Devices |

|---|---|---|---|---|---|

| Responding to Climate Change and Contributing to a Recycling-Oriented Society | Responding to Climate Change | Sales of machine tools certified as EcoBalance Machine,* LEDs for lighting, etc. | ● | ● | |

| Reduction of CO2 emissions, expansion of introduction of renewable energy, etc. | ● | ● | ● | ||

| Contributing to a recycling-oriented society | Sales of light-powered and mechanical watches, etc. | ● | ● | ||

| Reduction of water usage, promotion of recycling, management of hazardous chemicals, reduction of packaging materials, etc. | ● | ● | ● | ||

| Contributing to Better Quality of Life | Contribution to diverse lifestyles | Sales of wristwatches for the visually impaired, small switches for smartphones, etc. | ● | ● | |

| Contribution to medical care and healthcare | Sales of specimen-holding plates for bacterial analysis, thermometers and blood pressure monitors that are easy for anyone to use, etc. | ● | |||

| Providing Solutions in the Industrial Sector | Provision of labor-saving and automation solutions | Sales of machine tools certified as EcoBalance Machine* and machine tools equipped with LFV (low-frequency vibration cutting) technology, provision of numbered ticket systems and payment systems, etc. | ● | ● | |

| Contribution to mobility | Sales of components for advanced braking systems, communication systems, sensors, etc. | ● | |||

| Enhancing Job Satisfaction and Developing Human Resources | Enhancement of job satisfaction | Implement measures to realize employee well-being and improve employee engagement, provide training opportunities, implement health management measures, etc. | Group-wide | ||

| Development of human resources | Continue with the Group succession plan, develop human resources who will drive change, expand recruitment methods, and coordinate with the Group. | ||||

| Diversity, equity, and inclusion | Systematically train and promote female management candidates, encourage male employees to take childcare leave, implement measures to promote the active participation of diverse human resources, etc. | ||||

| Fulfilling Social Responsibility | Strengthening of risk management | Update and operate the Group significant risks, etc. | Group-wide | ||

| Enhancement of quality compliance | Conduct activities to promote the Quality Code of Conduct, etc. | ||||

| Respect for human rights and labor practices | Implement human rights due diligence, etc. | ||||

| Promotion of sustainable procurement | CSR procurement, green procurement, responsible minerals procurement, etc. | ||||

- * EcoBalance Machine: A selection of machine tools that meet our company’s internal standards and are part of our environmentally friendly product and technology product group, launched in fiscal 2024

Materiality KPIs

Please scroll down to see→

| Materiality | Main KPIs | FY2025 (Target) | FY2026 (Target) | FY2027 (Target) | |

|---|---|---|---|---|---|

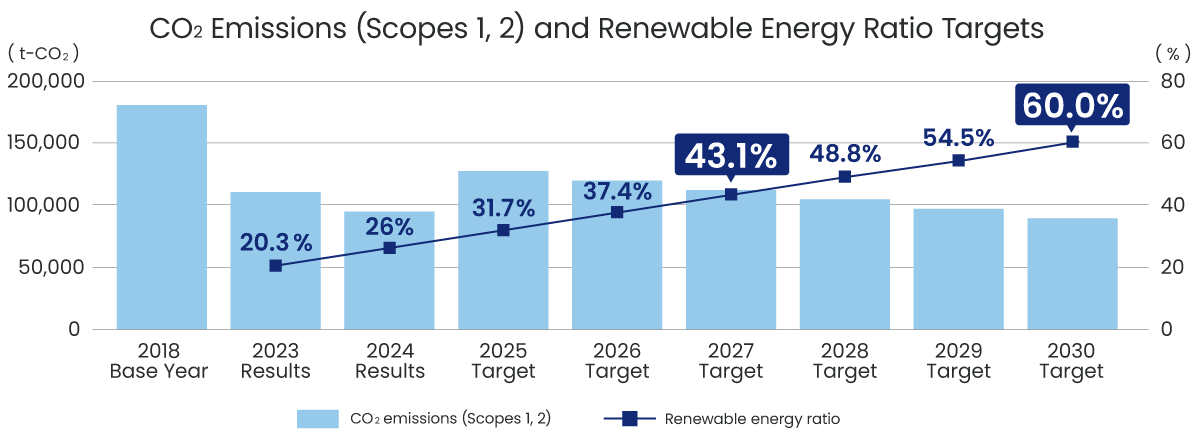

| Responding to Climate Change and Contributing to a Recycling-Oriented Society | CO2 emissions reduction rate (Compared to FY2018) |

Scopes 1 and 2 | 29.4 % | 33.6 % | 37.8 % |

| Scope 3 | 17.5 % | 20.0 % | 22.5 % | ||

| Renewable energy ratio (domestic + overseas) |

31.7 % | 37.4 % | 43.1 % | ||

| Sales ratio of sustainable products* | 24 % | 27 % | 31 % | ||

| Contributing to Better Quality of Life | |||||

| Providing Solutions in the Industrial Sector | |||||

| Enhancing Job Satisfaction and Developing Human Resources | Ratio of female management staff (CITIZEN WATCH) | 11 % | 12 % | 13 % | |

- * Sustainable products: Products and services that contribute to business growth while helping solve social issues linked to The CITIZEN Group’s materiality